-

Expediting & Inspection

We keep your suppliers on schedule, your equipment on specification, and your project on budget—through rigorous vendor inspections, proactive expediting and KPI‑driven reporting. GMS will participate as of your eyes and ears as an expediting partner.

Project Controls:

– Planning & Scheduling (Primavera P6 / MS Project)

– Baseline creation, updates, look‑ahead (1–4 weeks)

– Cost control, Cash Flow, Earned Value Management (EVM)

– Delay analysis (TIA/Windows), change & claim management

– Dashboards & reports (weekly/monthly), S‑Curve generation

– Resource loading, critical path & what‑if scenarios

– Risk AnalysisInspection (Third‑Party / Vendor)

– Document review: ITP, WPS/PQR, Material certificates (EN/ASME/API/IEC)

– In‑process inspections, witness/hold points, FAT/SAT/PSI

– NDT coordination (VT/UT/RT/MT/PT), coating & dimensional checks

– Vendor audits & assessments; compliance & conformity reportsExpediting

– Desk & Field Expediting: schedule checks, milestone tracking, bottleneck clearing, risk register, Weekly expediting progress reports & recovery plan

– Production capacity reviews and recovery planning

– Coordination of documentation, packing/marking, pre‑shipment readiness

– Early warning and escalation; OTD improvementDifferentiators

– Bilingual (DE/EN) team with international experience

– Established network of qualified inspectors across Germany & EU

– Transparent 24–48h reporting; live dashboards; KPI‑driven

– Vendor relationship management and proactive risk control

– Expediting visit to assess the supplier’s workload & control priorities

– Project Coordination and MonitoringDelivery Process

Kick‑off → Plan (ITP & Expediting Plan / Schedule Baseline) → Execution & Reporting → NCR & CAPA management → Close‑out & Lessons Learned

KPIs

– On‑Time Delivery (OTD) %

– Schedule adherence / variance /SPI, CPI

– S‑Curve (planned vs. actual vs. forecast)

– NCR closure time & punch‑list burn‑down

– Look‑ahead hit‑rate; recovery effectivenessCoverage & Response

Base: Düsseldorf • Coverage: Germany, EU, MENA (on‑site within 24–72h) • Remote expediting worldwide

-

Engineering Services

Green Minmet Solutions GmbH provides customized engineering services that cover every phase of a project, from the initial concept to full execution. This approach ensures that each solution is tailored to meet specific client requirements, technical standards, and operational goals.

Detailed Capabilities:

- Project Planning: Comprehensive project management, including feasibility studies, risk assessments, and resource allocation, to establish a clear roadmap for project success.

- Technical Execution: Expert implementation of engineering solutions, leveraging advanced tools, techniques, and industry best practices to bring projects to life efficiently and effectively.

- Quality Assurance: Rigorous quality control processes to ensure all aspects of the project meet high standards of reliability, safety, and performance.

-

Consulting

Our consulting services provide clients with insights into industry trends, sustainable practices, and ways to optimize operational efficiency. We offer strategic guidance to help clients stay competitive while aligning with environmental and economic goals.

Capabilities:

- Market Analysis: Detailed analysis of industry trends, competitor activities, and emerging opportunities to help clients make informed business decisions.

- Operational Consulting: Hands-on guidance to optimize production processes, minimize waste, and enhance productivity.

- Strategic Guidance: Development of long-term strategies that align with market demands, sustainability standards, and client growth objectives.

-

Mineral Process Planning

This service focuses on creating optimized, sustainable designs for mineral processing operations. We provide process planning solutions that balance productivity, efficiency, and environmental stewardship.

Capabilities:

- Productivity Enhancements: Tailored process designs that maximize throughput, minimize downtime, and reduce operational costs.

- Environmental Considerations: Integration of eco-friendly practices, such as water and energy conservation, to meet regulatory and corporate sustainability goals.

-

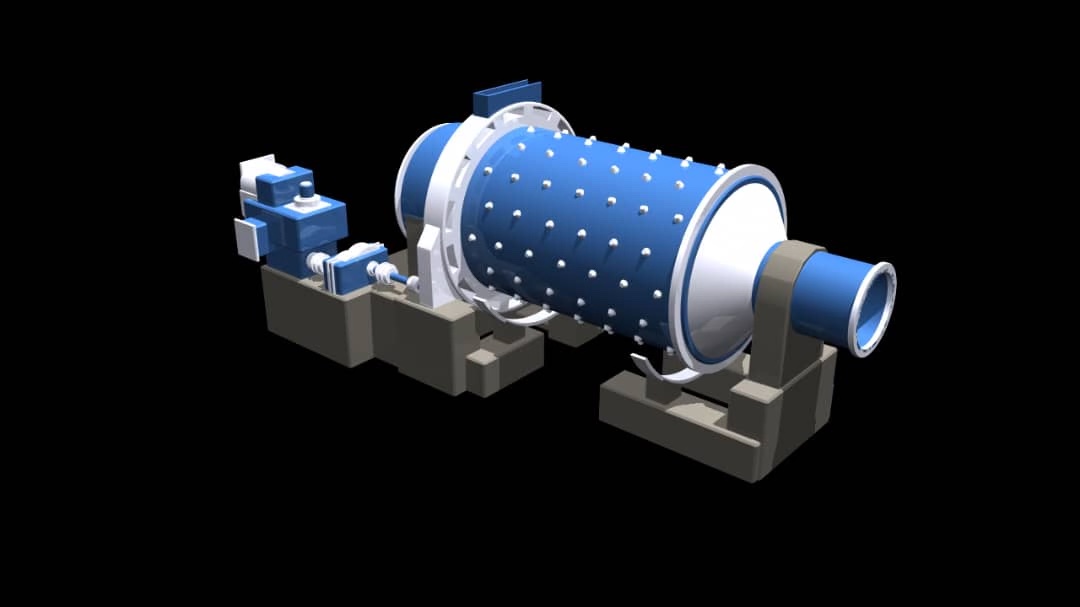

Machinery Supply and Trade

Green Minmet Solutions GmbH sources and supplies advanced machinery specifically designed for the mineral and metal industries. We focus on energy-efficient equipment that meets modern standards for sustainability and performance.

Capabilities:

- Vendor Selection: Careful selection of trusted vendors who provide reliable, high-quality machinery that meets the specific requirements of our clients.

- Equipment Evaluation: Rigorous assessment of machinery for energy efficiency, durability, and suitability for intended applications.

- Procurement: End-to-end management of the procurement process, ensuring that equipment is delivered on time, within budget, and ready for immediate use.

-

Engineering and Procurement (EP) Contracts

We offer comprehensive Engineering and Procurement (EP) contracts that cover the full lifecycle of a project. These contracts are customized to address specific client needs, ensuring that every project milestone aligns with budget, schedule, and sustainability goals.

Capabilities:

- Project Management: Coordination of all project activities, from design and procurement to implementation, ensuring that all components work seamlessly together.

- Cost Optimization: Strategic planning and resource allocation to minimize project costs without compromising quality or performance.

- Green Technology Integration: Incorporation of eco-friendly technologies that reduce environmental impact, improve energy efficiency, and align with regulatory standards.